7 Things About Amazon the Retail Supply Chain Needs to Know

It was nice a Sunday evening at Orlando Florida. Our company, Smart Gladiator, was one of the Start-Up Technology companies that was selected to represent the Georgia team in the Retail Industry Association (RILA) Retail Supply Chain Conference 2017.

The conference was full of educational sessions. Not just a source of subject matter experts discussing the major trends, the event was a great way to network and learn from other leaders and stalwarts of the Industry. The one that inspired me the most was a very down to earth, straight talk presentation by Crystal Hanlon, president of the Northern Division of The Home Depot. She emphasized, just getting work done is not enough. One needs also to showcase the work done, so everybody, especially the influencers that are going to impact how you grow, are aware of your accomplishments. You need to take time, strategize and have a regular action in place, to communicate and showcase your accomplishments in front of these executives, so you get what you deserve, Hanlon said. She talked about how she had set up quarterly networking and update events, to make sure initiatives had visibility with people in power.

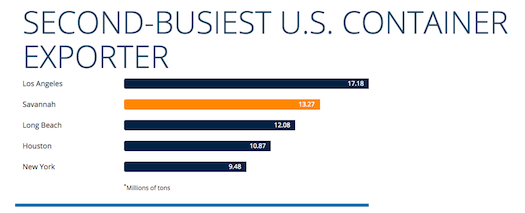

The highlight of the event was a dinner with the top supply chain influencers of the Georgia community. I learned that the Port of Savannah is the second largest port in the country in terms of the volume it handles. The Georgia team has done such an incredible job that there are other ports that are modeling their operations based on the Savannah port.

Photo Courtesy: the Port of Savannah

While all this conversation was going on, everybody is aware of the big elephant in the room: Amazon. We discussed how Amazon is changing retail at lightning speed. Here is a sampling of the news I heard:

- Amazon has built 46 distribution centers in the U.S. (accounting for about 2 to 2.5 million square feet in size) in the last few years. Not only that, Amazon has also pumped so much business out of these distribution centers (DCs) that they pay for themselves in just a year. All the Prime member business is being done from these distribution centers.

- Another major question everybody is asking is: Are retail stores dead? Overall, there is a paradigm shift that is driving lot more action back to the distribution center. That means less action at the stores, in general. Retailers are seeing a 2 to 3% growth in retail compared to a 30 to 40% growth in e-commerce. Of course, that translates into a labor shortage in the DC. I met with one retailer who is doing a lot of things to attract millennial workers. Their churn of the labor force is about 70%, so it is extremely important to have tools to enable workers to pick up quickly and work fast, while keeping it efficient.

- Amazon’s order fulfillment system is so slick. When any order that gets dropped in these DCs, it is shipped in 20 minutes or less. From my years at working with the leading software vendors, I know that even the best warehouse management systems can get orders shipped at the fastest was in six hours. As Amazon set this new standard, all major warehouse management system (WMS) vendors and solution providers are overhauling their solutions to meet or beat that 20 minutes. This has given rise to a new category of systems called Warehouse Execution Systems (WES).

- In another session, I heard that even the biggest retailers selling products on Amazon need to think carefully about pricing. In that digital marketplace, you need to price it right to be able to compete effectively with other brands. Basically, the efficiency gain needs to be passed on to the customer to win that sale. Popular brands are no exception to that rule.

- I’ve often said that traditional retailers can with Amazon by creating a personalized experience in their stores, by building relationship with the customers, and by solving their problems. Think about Best Buy and it’s work to put trained and knowledgeable sales associates on the floor and a Geek Squad of computer repair people in one corner. In the not to distant future, technology may allow the Amazon’s of the world to battle and win in this area. They’ll have an app for it. Think about an app where people can plug their Oculus Rift into their computer and virtually shop for the products they want. Virtually reality will change the way people shop and buy

- China is slowing down, so the drayage (companies that own the shipping vessels) service providers are looking for the U.S. market to absorb that capacity that has opened. China is looking more internally to do everything, especially with the train from China to London, about 8,000 miles.

- E-commerce is taking over other platforms in ways we never imagined. For example, Instagram is being used as an e-commerce platform to sell products. A bunch of businessmen in Dubai started posting pictures of products they wanted to sell on Instagram with Whatsapp contact information. Buyers would look at the product in Instagram, then buy by messaging through Whatsapp and pay through PayPal. The beauty of this is that all these services are free. None of this requires any infrastructure, so this seller has to purely focus on making the product, and then take attractive pictures and post them in Instagram along with the contact information. These businesses were generating anywhere from $2 million to $10 million in sales—pretty impressive for a small business.

Have you been to any great supply chain conferences lately? Let us know what you learned in the comments section below.

Originally published at Smartgladiator.com on Feb 28, 2018.

1. Increases EPP, using budgeted line items.

1. Increases EPP, using budgeted line items. Millennial friendly technology, less onboarding time, very easy adoption – touch screen keypad, and 43% of Millennials already use IOS, familiar with Facetime, 85% of Millennials aged 18-24 own devices and 86% aged 25-34 own them, consume a lot of video on their smartphones, and are highly comfortable with this medium, they understand and like apps.

Millennial friendly technology, less onboarding time, very easy adoption – touch screen keypad, and 43% of Millennials already use IOS, familiar with Facetime, 85% of Millennials aged 18-24 own devices and 86% aged 25-34 own them, consume a lot of video on their smartphones, and are highly comfortable with this medium, they understand and like apps.