Foster a Culture of Innovation in the Supply Chain

“Culture will eat strategy for breakfast, lunch, and dinner, anytime.” This was the first sentence that the professor of marketing and strategy uttered during our first MBA class at Georgia Tech. He underlined his point with the story of how Kellogg’s tried to conquer the Indian market with its breakfast cereal.

The company was trying to sell corn flakes with cold milk as breakfast in the Indian market, a culture that eats a warm breakfast finished with a hot, thick, creamy, flavorful coffee (A quick digression here: one of the most popular coffees in India is made from the freshest milk, gotten from “only grass” fed cows just minutes before). India already had popular and well-loved breakfast foods: the idli, a fermented and steamed rice cake with probiotic that makes digestion easier and is called “the most healthiest food ever” with double superlatives; and the dosa, a fermented rice crepe. The corn flake with cold milk did not take off as Kellogg’s expected because that product did not fit within the culture, especially among the South Indians.

This was a failed attempt at innovation. Which brings me to the question of today: How can one encourage innovation in the supply chain? Innovation tends to be considered a bad word in the supply chain space, because the supply function generally focuses on risk mitigation. The supply chain culture can be compared to the Asian culture or perhaps the military, which has a focus on conformity, simplicity, working together and taking orders through a chain of command. It’s not so much about standing out, but all about blending in. There is a laser focus on delivering merchandise in a mission critical fashion.

New ideas are often considered risky and non-conforming. Above all, nobody wants to lose his or her job. Also, a good number of folks in the supply chain leadership roles have a military background. When I worked for Hewlett Packard, many of the project managers and program managers came from the armed services. They were all hired for their leadership skills, but that came with this risk mitigating culture as well.

Knowing all this, it is really important to take extra steps to encourage and foster a culture of innovation. Innovation involves calculated risk taking, the ability to establish an effective process to learn from the mistakes, and an emphasis away from fear of failure and toward maximizing lessons learned.

Last month, I was at a prospect’s site and they wanted to thoroughly test our product as part of the technology selection process. They tested it in two facilities, using it for a couple of days in each. Basically, we deployed our product in all departments and tested thoroughly for all functions. The folks from the second facility did a much more thorough job and also had some very impressive innovations in their distribution center. These innovations were not necessarily in processes or products, but rather in the discipline, rigor, and daily habits, as well as within the overall culture of operations.

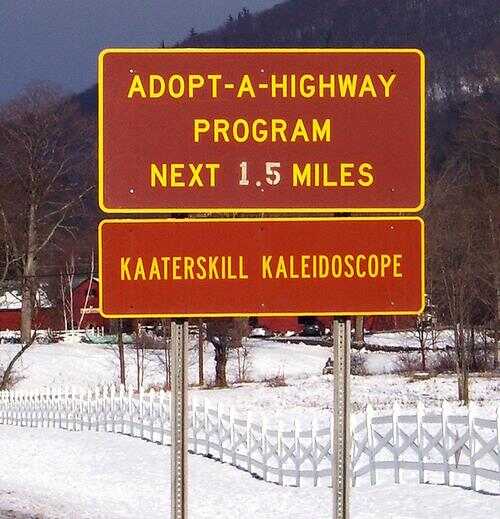

Where I live, we see green signboards on the highway that say this portion of the road is being taken care of by a certain organization, or sometimes even by an individual. Even in the Great Smoky Mountains, there are portions of the road that individuals can volunteer to maintain as part of the “Adopt a Trail” program and make a difference in the community. The folks at the second data center took this great idea and adapted it.

Photo courtesy: Daniel Case at the English language Wikipedia

Photo courtesy: Daniel Case at the English language Wikipedia

Every aisle had a picture of the associate with a sentence that said, “This aisle is maintained with pride by ” and then the name of the associate. The program ensures every aisle is kept clean, without overstock items left on the floor. Every aisle has an owner who is accountable. This is a simple idea is one that can be replicated in any DC without a large investment. Above all, it fosters a great sense of ownership in the associates and inculcated a great culture by leveraging pride and creating an enthusiasm that is contagious. This is the kind of innovation that changes the culture and fosters innovation in the cultural DNA of the organization.

Executive management can also encourage innovation. At one of our customers, for example, the senior vice president owns a patent for an innovative case used in their products. That sets the tone for the entire organization, starting from the top down. In addition, small innovations can make a big difference. I have also seen some really simple but specialized tools that make things better. For example, one company gave workers a small L-shaped tool to cut corrugated boxes, so the height of the box could be changed quickly and the box used for a different purpose. This simple change saved worker time, reduced waste, and encouraged re-use of boxes, which cut costs.

Organizations can approach innovation in two ways:

- By solving a specific problem that everyone is experiencing (i.e. fixing the existing mousetrap), or

- By making processes and products better (i.e. building a better mousetrap)

Within an organization, it is much easier to build momentum and acceptance for the first type of innovation. The second type required a lot more articulation of value proposition, better return on investment (ROI), and well-considered timing. To make it worthwhile, you need to create seven to 10 times more value on average to get traction with it. In short, it’s sometimes better to look for ways to make the mousetrap you have better.

Tell us about the challenges you’ve encountered while trying to innovate within your supply chain or in your distribution center. How did you overcome them? Does your organization encourage innovation? What steps have you taken to foster a culture of innovation? Let us know in the comments section below…and good luck innovating!

Originally published at Smartgladiator.com on Feb 28, 2018.

(Source: Pixabay)

(Source: Pixabay)

1. Increases EPP, using budgeted line items.

1. Increases EPP, using budgeted line items. Millennial friendly technology, less onboarding time, very easy adoption – touch screen keypad, and 43% of Millennials already use IOS, familiar with Facetime, 85% of Millennials aged 18-24 own devices and 86% aged 25-34 own them, consume a lot of video on their smartphones, and are highly comfortable with this medium, they understand and like apps.

Millennial friendly technology, less onboarding time, very easy adoption – touch screen keypad, and 43% of Millennials already use IOS, familiar with Facetime, 85% of Millennials aged 18-24 own devices and 86% aged 25-34 own them, consume a lot of video on their smartphones, and are highly comfortable with this medium, they understand and like apps.