Returning Goods in the Era of Experiential Retail

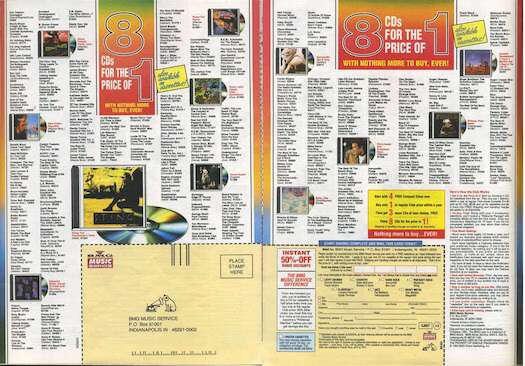

Back in the good old days (read the summer of 1999), I was introduced to a music and movie club from Columbia House or the BMG Music Service. You may remember the way it worked: They send you eight CDs of music or movies for a penny. Then they continue to send you titles, and you decide to keep them or send them back within 10 days. If you don’t send them back, your credit card is charged. And, of course, they keep sending you more—to get the free ones, you need to buy a certain number at the full retail price.

I was a young professional, trying to learn everything I could about technology and supply chain, and so I found that my friends and I had little time to watch and listen. My roommates and I spent our time working. We were like a lot of people: We didn’t have time to watch the movies and so we sent them back. It got me to thinking about the process that is necessary to process high level of returns. It would have to be agile, slick and fast to process the massive number of returns.

Retailers, distributors, and e-tailers all recognize that product returns are a necessary evil. Everyone hates it, from operations to IT to consultants, because processing returns tends to require manual intervention. Until recently, a person had to visually examine the product to determine the final disposition of it.

The rising number of on-line shoppers has made the massive problem more massive than ever before. Consider luxury brands that ends out a return label with every purchase. That means that returns are a normal part of today’s shopping process. It has to be as frictionless and easy for the consumer as the purchase is. The best retailers consider taking returns to be a part of building customer loyalty.

Let’s consider a typical return process:

- The customer has to call the retailer or distributor to get a Returns Authorization (RA#) number.

- The customer ships the product back with the RA#.

- At the distribution center, the returns personnel receives the product.

- An employee examines the product, detailing the condition of the product with a set of codes.

- Based on the condition code, the Warehouse Management System (WMS) determines the disposition code for the product, which range from restocking, making it a second for sale at the factory outlet, or dispose of it.

- The product is handled according to the code.

- The inventory is adjusted accordingly.

Now imagine all these steps performed for 1,000s of CDs coming every day. Just about every OEM and distributor has a similar challenge of a complicated, manual returns process in its supply chain operation. The increasing attention to environmental responsibility has, for the high-tech market, made the reverse logistics another big part of business.

As always, Amazon is an example of this issue writ large. They offer a large number of products and want to provide a notable customer experience. It may be that they feel the pain of returns more than anyone else. For their e-commerce operation to work, they need a sold end-to-end returns process. They decided to think outside the box and announced last month that customers could drop off returns at any Kohl’s department store. It has the potential to be a win/win. Amazon gets to make things easier for customers and the 1,100 Kohl’s stores across the United states get more people coming through the door. Those people may very well stay and shop. This may be the next progression of retail innovation, much like putting a large retailer as an anchor store at the mall.

As many other parts of the supply chain are automated in clever ways with machine learning (ML) and artificial intelligence (AI), it may also be time to look for an opportunity to leverage the same technologies to automate returns. That is a conversation for another time.

So what do you think? What’s the biggest challenge of product returns? What innovations could potentially make things better? Let us know in the comments section below.

Originally published at Smartgladiator.com on Jun 1, 2019.

1. Increases EPP, using budgeted line items.

1. Increases EPP, using budgeted line items. Millennial friendly technology, less onboarding time, very easy adoption – touch screen keypad, and 43% of Millennials already use IOS, familiar with Facetime, 85% of Millennials aged 18-24 own devices and 86% aged 25-34 own them, consume a lot of video on their smartphones, and are highly comfortable with this medium, they understand and like apps.

Millennial friendly technology, less onboarding time, very easy adoption – touch screen keypad, and 43% of Millennials already use IOS, familiar with Facetime, 85% of Millennials aged 18-24 own devices and 86% aged 25-34 own them, consume a lot of video on their smartphones, and are highly comfortable with this medium, they understand and like apps.