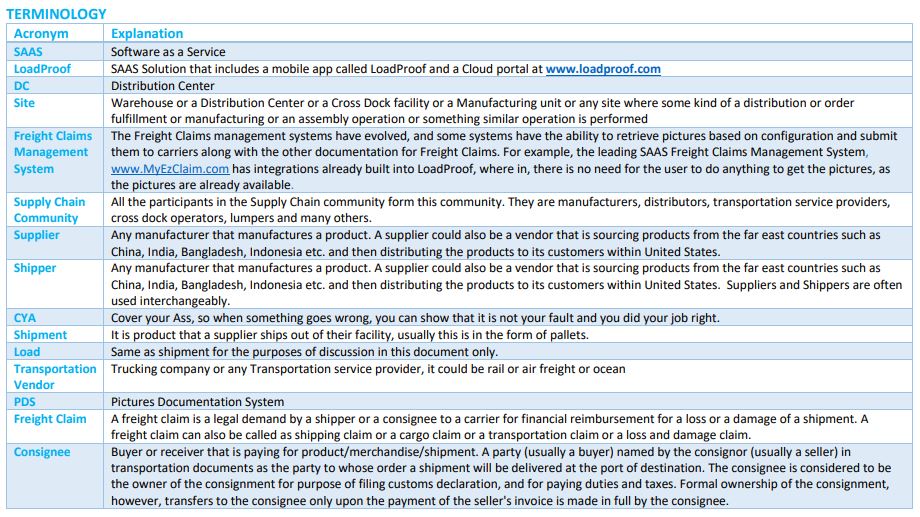

Picture Documentation for Freight Claims White Paper – Part I

How Picture Documentation will help with quicker Freight Claims resolution resulting in Cost Savings?

INTRODUCTION

This document describes the benefits of an effective Picture Documentation System(PDS) that helps with getting Freight Claims Paid faster. An effective pictures documentation system helps with

1 – Get Freight Claims paid much faster by making pictures available quickly and easily,

2 – Provides visibility to the damages through pictures. The visibility gained provides insight into the handling mistakes made while the orders are fulfilled, so that the parties can determine and establish accountability boundaries and get the shipper paid.

BACKGROUND

What are Freight Claims? A freight claim is a legal demand by a shipper or a consignee to a carrier for financial reimbursement for a loss or a damage of a shipment. Freight Claims are claims submitted by manufacturers/suppliers/shippers to transportation vendors and or carriers, when the goods the Supplier shipped did not arrive at the destination in a pristine state. Instead it arrived as damaged, the packaging was damaged or had scratches, dents, dings etc. So now the receiver cannot sell it, hence the Supplier wants the carrier to pay for the damages. So, the supplier is submitting a claim, claiming that it is the carrier’s fault that the damages occurred and hence the supplier needs to be reimbursed for the damage. At a high level there are 4 types of Freight claims

- Damage claims

- Loss claims

- Shortage claims

- Concealed Damage claims

The Freight Claims management systems have evolved in sophistication and some of the systems have the ability to retrieve pictures based on configuration and submit them to carriers along with the other documentation for Freight Claims. For example, the leading SAAS Freight Claims Management System, MyEzClaim.com has integrations already built into LoadProof, where in, there is no need for the user to do anything to get the pictures, because the pictures are already available.

Why do Suppliers have to deal with Freight Claims?

- Because the world is not perfect, mistakes happen, and humans make mistakes.

- There are several reasons why the damages occur to shipments that are shipped. Some of them are listed below:

- The warehouse personnel accidentally damaged the product during the loading process

- The warehouse personnel did not apply enough packaging for the shipment to sustain all the handling it went through.

- The truck driver applied brakes way too fast, which resulted in major G forces on the truck, hence the shipment/pallet/merchandise fell down and that caused the damage

- The truck driver did not take the route recommended by his GPS device, instead he took a high-altitude route going through the mountains, which resulted in a pressure difference situation, for example let us say all his potato chip bags burst and spilled over inside the truck

- The truck driver parked to take a break and his truck was vandalized for some reason

- There were bad people that stole from the truck

- The truck went through a cross dock facility or consolidation facility, where the people that moved the merchandise caused the damage

- At the receiving end, the receiver caused the damage by in appropriate handling

- If you are doing everything correctly, still your shipments are getting damages, then the Picture Documentation System will absolutely help you

- Are you applying enough packaging?

- Is your product in a good condition?

- Are you using correct box dims?

- Are you shrink wrapping as per the spec? White color/Black color/transparent – are you using the correct shrink wrapping?

- Are you using the correct number of layers while shrink wrapping?

- Are you floor loading or building pallets?

- If building pallets, are you building to the right height?

What is the best way to get Freight Claims resolved faster?

The best way to get your freight claims resolved quickly is to show that the shipment or load left your facility in perfect shape and or condition through pictures. When you show pictures, the person on the carrier end thoroughly sees everything and has proof to check on their side for any issues. If the retailer is paying for your transportation, then you will have to submit this to your retailer because the big retailers often pay themselves for transportation, so they will have to submit the Freight claims to the carriers, as they have the contract with the carriers.

What could have happened to the shipment/Load? Everything was fine when you shipped it, but it arrived damaged or it arrived with issues at the retailer facility, how did that happen?

There are multiple scenarios possible on what could have happened.

Scenario1 – Your trucking company messed up

- In this scenario the supplier is paying for the transportation, hence the supplier has the liberty to pick and choose the trucking company.

- However, the trucking company did not follow all the rules they were supposed to follow while handling the loads, which resulted in damages to your load.

Scenario2 – The retailer trucking company messed up

- In this scenario, the retailer you are shipping to is paying for transportation, because the retailer is leveraging their economies of scale and getting better rates, as they also have other product they pick up from other vendors in the vicinity.

- The problem here is that, because the retailer is paying for transportation, if the trucking company damages product, as a supplier you don’t have a solid voice to hold the trucking company accountable.

And how can this be addressed with a good Pictures Documentation System?

Scenario1 – Your trucking company messed up

- If you take pictures of the damages, then you can have a conversation with the trucking company and ask them to address these damages.

- You can even ask your customer on the other end to take pics of the condition of the product that they are receiving and then show the trucking company, the condition when the product left your facility and also the condition when the product arrived a their facility by taking pictures on both the instances.

- Then you can clearly hold the trucking company accountable and have a conversation with them and work through the Freight Claims process.

- Listed below are some of the things, that the trucking company is doing, that they are not supposed to do.

- Possibly going through the cross-dock facility, where your product is touched multiple times, even though they might have told you otherwise.

- Possibly depalletizing your pallets, which normally is not done and as a supplier you are not aware.

- Possibly placing nonfragile heavy items on your fragile products

- Possibly handling through an LTL truck, which as a supplier you are not aware of. It is perfectly fine to handle products as an LTL, but they need to let you know, so that you can reinforce on the packaging, such that the packaging enables more handling

- Just keep in mind that, it is not a good idea to have a stand-offish conversation, however work with them as a partner and get the issues addressed in a collaborative manner.

Scenario2 – The retailer trucking company messed up

- If you take pictures of the damages, then you can have a conversation with the Retailer and tell them that the damages were not there when the product left your facility. Possibly have the retailer submit Freight claims on behalf of the merchandise you shipped and get them to address the issue.

- You can even ask your Retail customer on the other end to take pics of the condition of the product that they are receiving and then show the retailer, the condition when the product left your facility and educate them on what is happening to the product.

- Listed below are some of the things, that the trucking company is doing, that they are not supposed to do

- Possibly going through the cross-dock facility, where your product is touched multiple times, even though they might have told you otherwise.

- Possibly depalletizing your pallets, which normally is not done and as a supplier you are not aware.

- Possibly placing nonfragile heavy items on your fragile products.

- Possibly handling through an LTL truck, which as a supplier you are not aware of. It is perfectly fine to handle products as an LTL, but they need to let you know, so that you can reinforce on the packaging, such that the packaging enables more handling.

- Just keep in mind that, it is not a good idea to have a stand-offish conversation with the retailer, however work with them as a partner and get the issues addressed in a collaborative manner.

- Large companies have plenty of inertia in their organization, so provide enough pictures proof to demonstrate you are doing your job right, then your partner on the retailer side, can share these with his bosses and get the situation addressed.

- Be cognizant of the fact that the Supply Chain is a community and work with all the partners in the Supply Chain in a collaborative manner, that will help you get your issues addressed. If you follow a stand-offish approach, then you will not be able to get your issues addressed quickly and effectively.

What is the most important thing in this entire Freight Claims Conversation?

The most important thing to have an effective conversation with your Supply Chain partners is Pictures for the reasons below.

- The Supply Chain has gotten very complex and there are way too many operators in each Supply Chain, very few people realize this.

- You don’t have control over who touches the product you ship. LTL terminals, Transportation companies, Truckers, Lumpers, other Intermediaries, Ports if International, Receivers etc.

- Very few Warehouse Managers understand this, realize this and recognize this.

- There are way too many people touching any product you ship in the Supply Chain today, so a lot could go wrong, especially LTLs – LTLs – work on a hub & spoke model.

- So you need to make sure you have proof to show that you did your job right, just in case something goes wrong.

- For example, nowadays When Amazon makes a delivery at your house, there is a picture of the product they left at your doorstep – to show that they did their job right & Anything that happens after that – it is not their fault.

- That is why it is important to do your CYA, always have proof that you did your job right.

- And so pictures are the best way to show that you did your job right.

- It is not your fault because – The fact is there are so many operators in the Supply Chain that are touching the product you ship and you have no idea who is touching that product and who is handling that product appropriately & who is not.

- Pictures are the best Proof – You cannot argue with Pictures – Pictures help with resolving issues so much faster, so the best proof (CYA) is pictures.

- A picture is worth 1000 words.

- If you can get videos that is even better, as videos don’t lie.

How do pictures help getting your problems addressed while operating in a Supply Chain community?

The following are the reasons how showing pictures helps with getting your issues addressed within the Supply Chain community

- When you show pictures, you come across as transparent, people trust you and people are willing to work with you

- Now with the proliferation of Smart Phones in everyone’s hands, pictures have become a very important part of our lives and they become a basic expectation and a necessity. It is very common to ask for a picture in any conversation, hey can you quickly snap a picture of that thing and text it to me please? It just helps understand the situation in a crystal-clear fashion. If you don’t provide pictures, you are looked upon as you are hiding something, and you are not considered trustworthy.

- Once such a crystal-clear visibility is provided on the situation to all parties involved, it is much easier to build consensus and get everybody to act upon to get the issue resolved faster.

What are some of the current methods of capturing picture documentation?

The following are the different methods of capturing picture documentation that are widely used

- None – there is none whatsoever.

- Old School Digital Cameras.

- Usually there is an operator that takes pictures of outbound loads.

- After taking certain number of pictures, the memory card gets full.

- At this point the operator walks down to his computer, inserts the memory card into his computer, copies the pictures into this computer or sometimes the pictures are copied into Google drive.

- Then there is another employee that goes to the computer and or the Google drive and updates the pictures with the relevant contextual data. Not everybody does it with discipline.

- Operators using their personal smart phones.

- Operators use their personal smart phones and take the pictures.

- Then they email the pictures to themselves and or their colleagues

What are some of the drawbacks with the current methods of capturing picture documentation?

- None – This is not good, no pictures whatsoever.

- Old School Digital Cameras.

- The problem with this system is that this is the least efficient system.

- Way too much labor is spent on the following

- Taking pictures, walking down to the computer and copying them – this creates bottle necks in the current processes, such as loading especially during the peak time in the evenings when the shipments are prepared to sent out.

- There is another employee that performs the tagging of the pictures with the relevant contextual data, which is extra labor that is spent on this activity.

- This system also creates bottle necks while performing important steps during shipping of loads.

- Many distributors have tried this to make it work but abandoned this process due to the inherent inefficiency in this process.

- Using personal smart phones

- This solution temporarily solves the problem but does not help after 3 months or 4 months, when a claim is submitted, and the pictures are needed the most

- At that time, nobody knows where the pictures are. Operators and supervisors end up searching for pictures in their smart phones, inboxes, computers etc. but realize they are nowhere to be found.

What are the most important capabilities that a Picture Documentation System needs to have?

The core in the Picture Documentation system is to have the ability to do the following

- High-speed picture taking,

- High speed picture tagging with appropriate meta data,

- High Speed picture uploading

- A failsafe repository of pictures, where pictures are never lost and that can be accessed by anybody and everybody in a controllable fashion

- High speed picture retrieval capabilities and

- High speed picture sharing capabilities so that there are no bottle necks added to the current processes.